The exploding GM limited slip differential

While towing to Track Night at Atlanta Motorsports Park I noticed a strange noise. I kept thinking it was from the trailer or the weight distributing chains. I stopped several times to

I noticed the noise was mostly after left-hand turns and was getting worse. As I crossed the railroad track 9 miles from my destination there was a very loud pop. That was when I realized the noise was coming from the rear differential of the Suburban

I drove as gently as possible on the curvy road to the race track. But when I started up the steep entrance to the guard shack, I began to wonder if I would make it. The noise and shudder

I made it to my paddock spot and got the race car ready and got registered. Then I set about deciding how to get home. My co-driver for the event had driven his 2500 pickup so we decided to load the Suburban on the race car trailer and let him tow it home. That put me driving the Porsche home. It is tagged and insured so that was legal. Just not very comfortable.

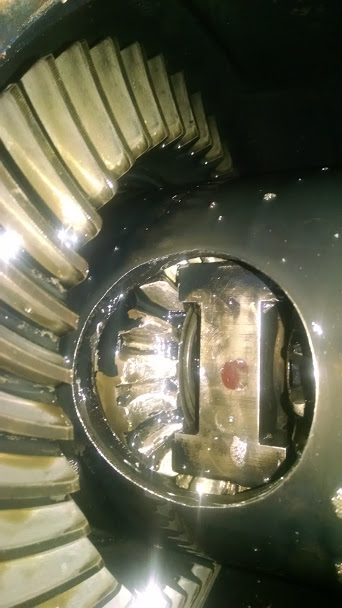

Once everything was home and unloaded I put the Suburban on the lift and popped the cover to see what broke. As I suspected, it was a spider gear.

What I did not know before removing the cover was that I had a G80 limited slip differential. That explains how I have been able to pull a loaded trailer to the campsite in Harlan and even make it to the top of the

The G80 does work well at low speeds. However, it is a very strange design. One website described the internals as looking like a clock. East Cost Gears

The gearbox works by having a governor that detects a difference in speed between the two axles. Once the little governor goes balls to the wall, it presses a wedge into the spider gears to lock them together. Very effective, but very hard on the spider gears. After 250,000 miles of abuse, my had had enough.

I have found that replacement spider gears are simply not available. So I will either replace the unit with a normal positraction or maybe search for a used G80 to keep the truck as equipped.

Update: I found a nice G80 on eBay! It arrived nicely packed;)

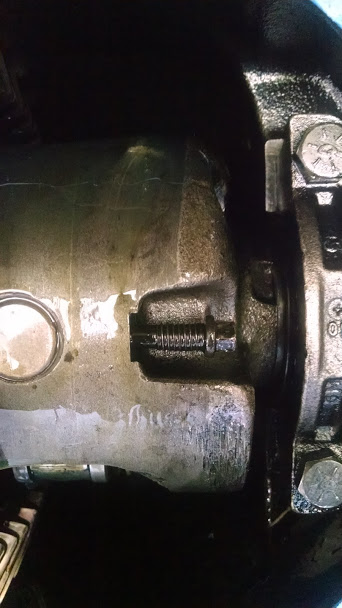

After removing the cover and draining the fluid, I removed the retaining bolt for the cross pin. This bolt normally has locktight on it. So be sure to use a six point wrench to get it out. Heat may help but mine came out with just some muscle.

With the cross pin out, I removed the wheels and brake drums. I them pushed in each axle to free its C clip. It took some maneuvering to get the C clip aligned with the narrow slot it can come out through. I used a magnet to fish them out.

With the axles out of the way, I loosened the carrier cap bolts and removed the G80 from the axle. I made sure to note the orientation of the carrier bearing caps and the shims packs on each side.

Next I used some brake cleaner to clean all the metal particles from the differential housing. There were lots of broken teeth and other mystery chunks in the bottom.

I had to swap over my ring gear to the replacement carrier. Note that these bolts are left hand threads so set the impact to tighten to loosen them. I carefully tapped the ring gear into place and used the ring gear bolts to pull it down carefully. I probably could have heated it up to make it easier but it went on fine like this.

I could not fit the carrier in my vise so I reinstalled the whole carrier and held the driveshaft to torque the ring gear bolts to 65 ft lbs. I discovered one of my torque wrenches will not click in reverse but the other one would.

I then tightened the carrier bearing cap bolts to 60 ft lbs. I used the same shims as came out in the same positions. I did not do a complete check of the gear sweep or pinion preload. I just checked by hand that everything felt fine and I decided to just run with it.

After installing the axle shafts, I then replaced the cover with new gasket and filled the housing with fresh grease. The fill hole is on the right side of the axle housing not in the cover like on Jeeps.

After buttoning it all back up, I took it for a test drive to see how it sounded. No more clunking was good. And there was no whine at speed so the shim choice must have been close enough also.

Here is an entertaining that shows the G80 is better than an open differential.